Three Key Points to Differentiate Fused Magnesia and Large Crystal Fused Magnesia

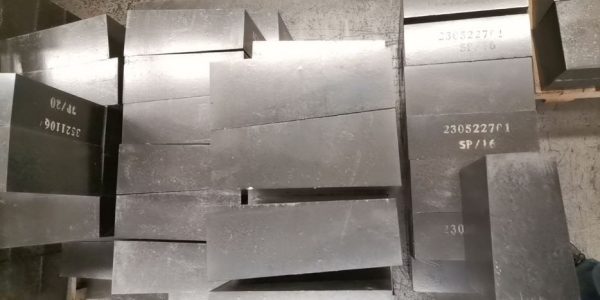

Fused Magnesia and Large Crystal Fused Magnesia are both high-performance magnesia refractory materials with extensive industrial applications. However, they differ significantly in raw materials, preparation processes, chemical and physical properties, and application fields. 1. Raw Material Sources and Preparation Processes Fused Magnesia Sand: Made from magnesite ore containing more than 47% magnesium, directly melted. This…