What Are The Common Refractory Materials For Blast Furnace?

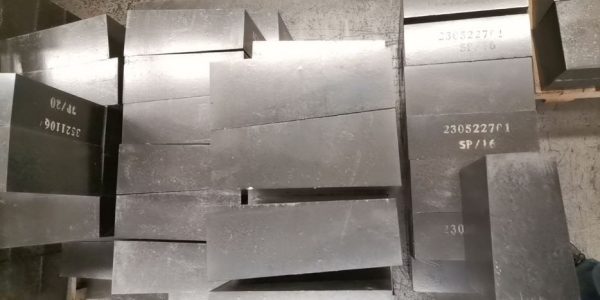

In the early stages of long process steelmaking, the blast furnace is a shaft furnace that burns coke by blowing hot air and reduces iron ore to hot metal. It is a thermal device for the continuous production of iron in a high temperature and reducing atmosphere. Refractory Materials for Blast Furnaces 1.Anhydrous clay Anhydrous…