Refractory Characteristics of Calcined Bauxite

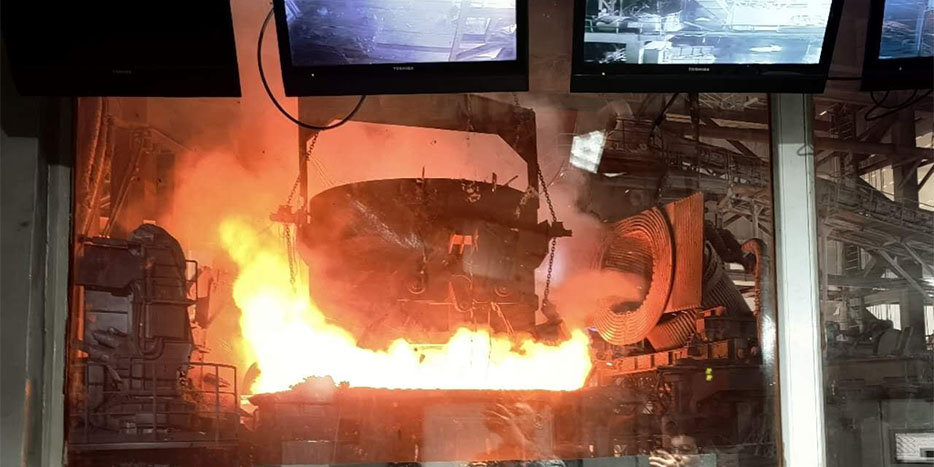

Calcined bauxite is one of the refractory raw materials, it is sintered after high-temperature treatment, ( Normally sintered it in rotary kilns, round kilns, or shaft kilns at temperatures around 1600°C – 1800°C), alumina (Al2O3) content ranging from 70% to 90%. The excellent refractory properties of calcined bauxite make it one of the main raw materials for the production of shaped and unshaped refractory material.

Strictly Quality Control to Ensure Quality

We implement strict quality control of calcined bauxite to ensure that each batch of product meets high standards. Calcined bauxite refractory raw materials are able to meet the high standards of customers in terms of chemical stability and physical properties.

Product sampling inspection

Calcined Bauxite Products Can Be Customised

According to different customers’ application scenarios, we can match calcined bauxite products with different index specifications as required. To meet the needs of high alumina refractory materials, refractory casting materials, refractory bricks and so on. At the same time, we are committed to providing customers with more comprehensive solutions, covering refractory performance, stability and after-sales products and other aspects.

Technical Support & R&D

Our professional technical team provides you with comprehensive technical support and consultation to ensure that calcined bauxite gives full play to its performance advantages in use. The R&D team is committed to continuous innovation to provide more advanced and reliable solutions. And we attach great importance to customer experience, not only provide quality products, but also actively communicate and cooperate with customers. We continuously listen to customer feedback and improve our services to ensure that our customers get maximum satisfaction from working with us.

Contact Us

Related Posts

Three Key Points to Differentiate Fused Magnesia and Large Crystal Fused Magnesia

Optimizing Refractory Solutions with Large Crystal Fused Magnesia