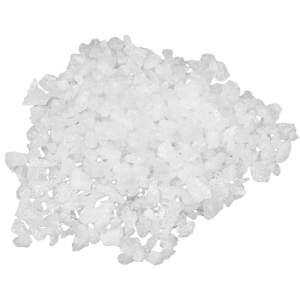

Sintered Magnesia-Alumina Spinel

Sintered Magnesia-Alumina Spinel

Sintered magnesia-alumina spinel is sintered with high quality bauxite and magnesia through a multi-stage homogenization process at high temperatures above 1800℃. With erosion resistance, abrasion resistance, peeling ability, good slag resistance, good thermal shock stability, high temperature resistance and other performance characteristics.

Sintered magnesia-alumina spinel is an ideal raw material for high-temperature zones such as cement and lime rotary kilns, and refractory products such as ladle lining bricks and ladle castables.

| Item | ZTR-SMAS1 | ZTR-SMAS2 |

| Al2O3 (%) | 64-66% | 74-76% |

| MgO (%) | 32-34% | 21-23% |

| CaO (%) | 0.8-0.85% | <0.7% |

| SiO2 (%), < | 0.5% | 0.5% |

| Fe2O3 (%), < | 0.5% | 0.5% |

| Bulk Density (g/cm3), ≥ | 3.25 | 3.25 |