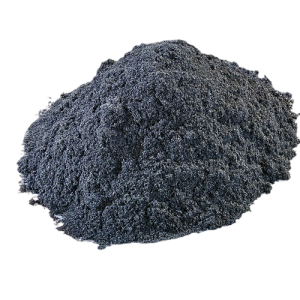

Calcined Bauxite

Calcined Bauxite

Calcined bauxite is a good raw material for the production of shaped and unshaped refractory products. Calcined bauxite is produced by sintering raw alumina bauxite in a rotary kiln, round kiln or shaft kiln at high temperatures (typically around 1600℃-1800℃).

Due to its high mechanical strength, thermal stability and slag resistance, calcined bauxite is widely used in the steel industry, foundries, glassworks and cement plants for the production of various shapes and types of refractory materials.

| Item | ZTR-CB75 | ZTR-CB80 | ZTR-CB85 | ZTR-CB86 | ZTR-CB87 | ZTR-CB88 | ZTR-CB90 |

| Al2O3 (%), ≥ | 75 | 80 | 85 | 86 | 87 | 88 | 90 |

| Fe2O3 (%), ≤ | 3.0 | 3.0 | 2.0 | 2.0 | 2.0 | 1.8 | 1.8 |

| TiO2 (%), ≤ | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| K2O+Na2O (%), ≤ | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.25 | 0.25 |

| CaO+MgO (%), ≤ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Bulk Density (g/cm3), ≥ | 2.70 | 2.80 | 3.00 | 3.10 | 3.20 | 3.25 | 3.30 |

| Size | 0-1mm, 1-3mm, 3-5mm, 5-8mm, according to customer's requirement. | ||||||