Zhong Tang (ZTM) at ANKIROS/ANNOFER/TURKCAST 2024

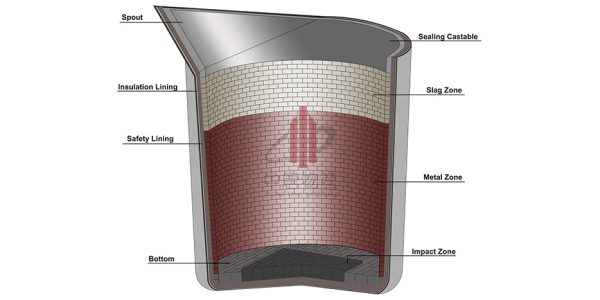

Zhong Tang (Dalian) Materials Co., Ltd (ZTM) will participate in the ANKIROS/ANNOFER/TURKCAST 2024 exhibition, held from September 19 to 21, 2024, in Istanbul, Turkey. ZTM has established long-term partnerships with numerous large steel plants and refractory material manufacturers in the Middle East market and looks forward to engaging with more partners at this exhibition to expand business opportunities. Exhibition Information: Exhibition Name: ANKIROS/ANNOFER/TURKCAST 2024 Exhibition Venue: Istanbul Expo Center (İstanbul Fuar Merkezi), Turkey Exhibition Dates: September 19 – 21, 2024 Booth Number: H5-F150 Refractory Product Display and On-site Consultation At the exhibition, ZTM will showcase a range of shaped and unshaped refractory materials, including magnesia-carbon bricks, ramming mass, gunning materials, castables, nozzles, stoppers, slide gates, as well as fused magnesia, white fused alumina, alumina, bauxite, and other refractory raw materials. We will bring actual products and models for customers to experience and provide on-site consultation to ensure you have a comprehensive understanding of our refractory products and services. Some of the exhibits at ANKIROS/ANNOFER/TURKCAST 2024 Comprehensive Refractory Solutions ZTM not only offers high-quality refractory materials but is also dedicated to providing comprehensive technical support and customized services to our customers. Our R&D team continuously innovates to ensure stable product quality. Through rigorous quality control and consistent supply, we help customers improve production efficiency. Our after-sales team is also ready to provide on-site services to promptly respond to your needs. After-sales team on-site service Re-inspect before shipment Sharing Cutting-edge Refractory Technology Globally At the ANKIROS/ANNOFER/TURKCAST 2024 exhibition, ZTM will actively participate in global exchanges and cooperation on refractory technology, showcasing our professional capabilities and engaging in deep communication with potential global partners to further strengthen our market position. We Sincerely Invite You to Visit ZTM’s Booth We cordially invite you to visit ZTM’s booth H5-F150 and engage in face-to-face discussions with us. If you are interested in our refractory materials or solutions, feel free to consult us at any time. We look forward to meeting you at the exhibition and exploring future cooperation opportunities together. Contact Us Related Posts More Blog