The Uses and Advantages of Magnesium Carbon Bricks in Steel Making Industry

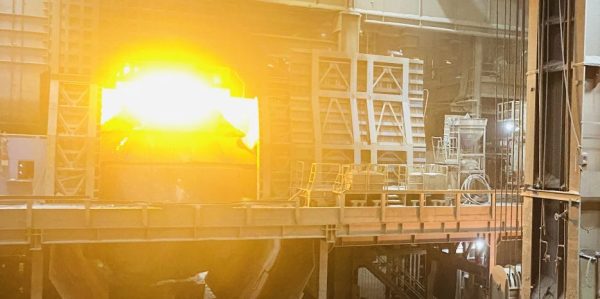

In the realm of iron and steel metallurgy, the choice of construction materials for steelmaking furnaces holds paramount importance. Among these materials, magnesium carbon bricks, renowned for their exceptional refractory properties, have emerged as a popular choice. This blog presents an overview of the characteristics, production process, and the extensive applications of magnesium carbon bricks within the steel smelting industry. 1. Characteristics of Magnesium Carbon Bricks: Magnesium carbon bricks are engineered from premium graphite and high-purity magnesium oxide, crafting high-performance refractory materials known for the following attributes: Lightweight and High Strength: Magnesium carbon bricks boast low density yet impressive strength, facilitating ease of processing and construction. Robust Corrosion Resistance: These bricks can endure corrosive environments, effectively extending the service life of furnace linings. Exceptional Fire Resistance: Thanks to the high melting point of magnesium oxide, these bricks can withstand temperatures exceeding 1500°C. Superior Electrical Conductivity: Magnesium carbon bricks exhibit robust electrical conductivity, capable of resisting arc burn-through, ensuring the stability of the furnace lining. 2. Production Process of Magnesium Carbon Bricks: The production process of magnesium carbon bricks encompasses the following sequential steps: Crushing: Raw materials are initially crushed to facilitate subsequent mixing and molding. Sampling: Quality sampling of the crushed raw materials is performed to ensure compliance with defined requirements. Mixing: The crushed raw materials are blended to create a homogeneous mixture. Inspection: Rigorous inspection of the mix confirms that its composition and properties meet predefined standards. Batching: Based on production schedules and customer specifications, the mixture and auxiliary materials are batched. Inspection: Post-batching inspections are conducted to validate the composition and performance of the products. Molding: The batched products undergo molding and processing to produce magnesium carbon bricks that meet the required specifications. Calcination: The molded magnesium carbon brick products are subjected to high-temperature calcination to complete material densification and optimize performance. Inspection: A final check is conducted on the calcined magnesium carbon brick products to ensure they meet quality and performance criteria. 3. Application of Magnesium Carbon Bricks in Steel Making Industry In steelmaking electric furnaces, the advantage of magnesium carbon bricks lies in their excellent refractory properties and high temperature strength. Due to its high melting point, magnesium carbon bricks can withstand the high temperature environment in the process of high temperature steelmaking, effectively protecting the furnace lining and extending the service life of the furnace. In addition, magnesium carbon brick also has excellent anti-erosion performance, can resist the erosion of impurities in steel, to ensure the quality of steelmaking. In converter applications, magnesium carbon bricks assume a pivotal role as the primary material for converter linings due to their remarkable thermal shock resistance and resistance to slag erosion. They are suitable for all converter types, ranging from large to small converters. In ladle applications, magnesium carbon bricks are favored as ladle lining materials, thanks to their excellent refractoriness and resistance to molten steel erosion. They accommodate various ladle sizes, from large to small. Furthermore, magnesium carbon bricks find extensive use in electric furnace linings and diverse high-temperature equipment applications. In conclusion, magnesium carbon bricks are highly regarded within the realm of iron and steel metallurgy as high-performance refractory materials. Their exceptional performance and versatile applications contribute to the efficiency, stability, and sustainability of iron and steel metallurgical production. With the continuous advancement of science and technology, it is anticipated that the performance and application scope of magnesium carbon bricks will undergo further expansion and enhancement in the future.