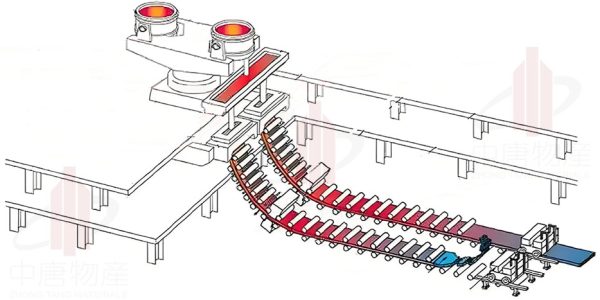

In extreme high-temperature, highly corrosive industrial environments like steelmaking, a specific refractory material withstands the demanding conditions, ensuring the smooth operation of steel production—the Magnesia Carbon Brick (MgO-C Brick). As a high-performance composite refractory, magnesia carbon bricks play a crucial role in modern industry. Whether you are new to the field of refractories or seeking a systematic understanding of the fundamentals of this vital material, this article offers a comprehensive introduction. For in-depth technical details on magnesia carbon bricks: Link to: Engineer’s Guide – Deep Dive into Performance and Application Optimization Strategies Interested in procurement and costs? Link to: Procurement Guide – Beyond Price: TCO Analysis and Supplier Value Assessment for Magnesia Carbon Brick Procurement What are Magnesia Carbon Bricks? Magnesia carbon bricks are a type of unburned refractory. They are manufactured from raw materials including fused or sintered magnesia, flake graphite, organic binders (like tar, pitch, or synthetic resins), and antioxidants (such as metal powders like aluminum and magnesium, or non-oxide materials like carbides), processed through high-pressure forming and subsequent heat treatment. Simply put, magnesia carbon brick is a composite material ingeniously combining the high refractoriness and resistance to basic slag erosion of magnesium oxide (MgO) with the excellent thermal shock resistance and low wettability of carbon. Manufactured via specific formulations and processes, it is primarily used in demanding high-temperature industrial sectors, especially steelmaking. Custom Solution Consultation What are the Main Components of Magnesia Carbon Bricks? Main components include: 1) Magnesium Oxide (MgO) aggregate, providing refractoriness and slag resistance; 2) Graphite, enhancing thermal shock resistance and reducing infiltration; 3) Binders, used to bond the raw materials; 4) Antioxidants, protecting graphite from oxidation. Magnesium Oxide (MgO): Forms the primary aggregate structure, typically using high-purity fused magnesia (FM) or sintered magnesia (dead-burned magnesia, DBM). The purity, crystal size, and density of the MgO directly impact the final product’s slag resistance and high-temperature stability. (For an in-depth discussion on how raw materials affect performance, see [Link to: Engineer’s Guide – Section on Raw Material Impact]) Carbon Source: Primarily high-purity flake graphite. Graphite imparts excellent thermal shock resistance to the brick and reduces its wettability by molten slag and steel, thereby preventing erosion. The quality and content of graphite are critical parameters. Binders: Such as phenolic resins or pitch, used to firmly bind the particles together during forming and heat treatment, developing strength. The type of binder influences the final carbon bonding network. Antioxidants: Such as metallic aluminum powder, magnesium powder, or carbides (e.g., SiC, B4C). Since graphite readily oxidizes at high temperatures, these additives react preferentially at elevated temperatures, protecting the graphite and extending the material’s service life. (The mechanism of antioxidants is key to magnesia carbon technology, detailed in [Link to: Engineer’s Guide – Section on Antioxidant Function]) Custom Solution Consultation What are the Key Performance Characteristics of Magnesia Carbon Bricks? Key properties include: High refractoriness (>1800°C / 3272°F), excellent resistance to basic slag corrosion, good thermal shock stability, high strength and low creep at high temperatures, and low wettability by molten metal/slag. These properties result from the synergistic interaction of the various components. For instance, MgO provides the fundamental refractoriness and chemical resistance, while graphite primarily contributes to resistance against thermal fluctuations and infiltration. Antioxidants are added to overcome graphite’s susceptibility to oxidation. In practical applications, balancing these performance indicators according to specific operating conditions is crucial. (How to balance properties for different conditions? See [Link to: Engineer’s Guide – Section on Performance Balancing and Material Selection]) Where are Magnesia Carbon Bricks Primarily Used? Widely used in the high-temperature core equipment of the steelmaking industry, such as the linings of Basic Oxygen Furnaces (BOF), Electric Arc Furnaces (EAF), Steel Ladles, and secondary refining units like RH and LF degassers, especially in severe wear areas like slag lines and hot spots. In these applications, magnesia carbon bricks must withstand extremely high temperatures, chemical corrosion and physical erosion from molten slag, and frequent temperature fluctuations. Different areas within the equipment, like the converter mouth and slag line, EAF hot spots, and ladle slag lines, experience vastly different conditions, thus requiring magnesia carbon bricks with different performance focuses. What are the Common Product Classifications or Grades of Magnesia Carbon Bricks? Magnesia carbon bricks can be classified based on binder type (resin-bonded vs. pitch-bonded), carbon content (e.g., regular carbon, low carbon, ultra-low carbon), MgO raw material grade (fused magnesia-based vs. sintered magnesia-based), antioxidant system, or specific properties (e.g., high slag resistance, high thermal shock resistance). Suppliers offer various grades to meet diverse application requirements. Common classifications include resin-bonded and pitch-bonded types; distinctions based on carbon content such as regular, low, and ultra-low carbon; and differentiation by MgO source (fused vs. sintered). Furthermore, different antioxidant formulations create distinct product series. The choice of grade depends on the specific operating environment and cost-effectiveness considerations. (Grade selection directly impacts cost and lifespan. How to conduct a value assessment? See [Link to: Procurement Guide – Section on Value Assessment and TCO]) Custom Solution Consultation Mgo-c Brick Grades How are Magnesia Carbon Bricks Manufactured? The manufacturing process mainly involves: Raw material crushing and screening, precise batching and mixing according to formulation, forming using high-pressure presses, heat treatment (curing/tempering) at specific temperatures, and finally, inspection and packaging. This process requires strict quality control. Factors like particle size distribution of raw materials, uniformity of mixing, forming pressure, and the heat treatment temperature profile significantly affect the final product’s performance and consistency. High-quality magnesia carbon bricks depend on precise manufacturing techniques and rigorous process control. (Manufacturing process stability is key when evaluating suppliers, see [Link to: Procurement Guide – Section on Supplier Quality Control]) What are the Main Advantages of Using Magnesia Carbon Bricks? The main advantages include significantly extending the service life of high-temperature equipment, reducing downtime for repairs thereby increasing production efficiency, ensuring stable and safe production processes, and meeting the demanding requirements of modern metallurgical processes. Due to their outstanding overall performance, magnesia carbon bricks have become indispensable key refractory materials in modern high-temperature industries, particularly steelmaking. They…