Purging Plug & Well Block

Uniform molten steel temperature, ensuring steel quality

Purging Plug & Well Block

![]() Long-life Design

Long-life Design

Materials and structures selected based on steel grades, smelting processes, and ladle capacity, extending plug service life.

![]() Sealing Design

Sealing Design

Special sealing materials and structures prevent gas leakage and improve stirring efficiency.

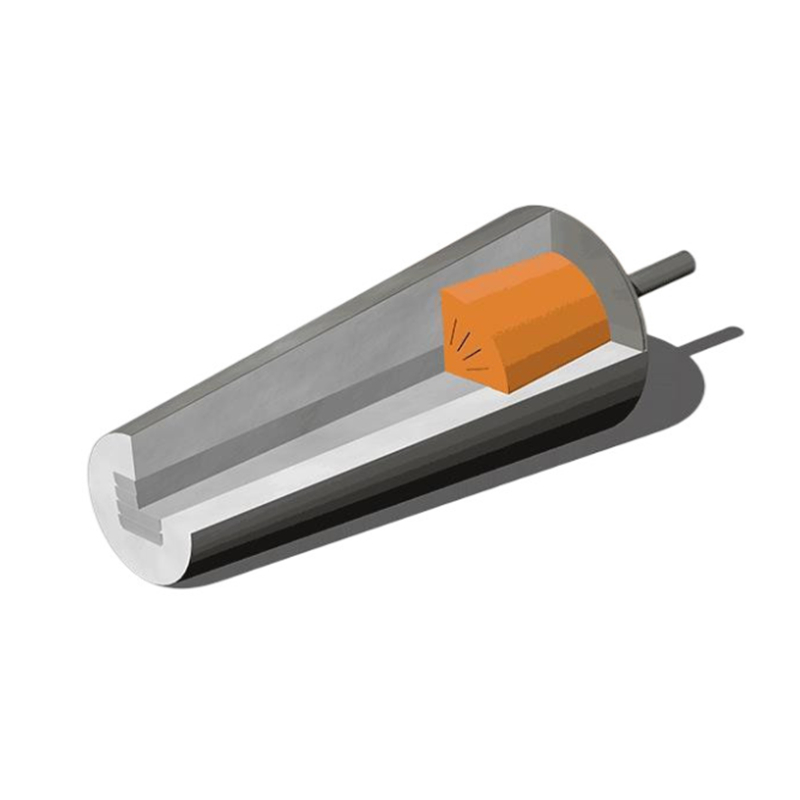

![]() Structural Design

Structural Design

Different purging plug core structures designed according to refining process requirements.

| Name | Purging Plug | Well Block | ||||

| Brand | ZTM-T1 | ZTM-T2 | ZTM-T3 | ZTM-TZ1 | ZTM-TZ2 | ZTM-TZ3 |

| Al2O3+MgO+CrO (%) | ≥96.0 | ≥94.0 | ≥92.0 | ≥96.0 | ≥92.0 | ≥92.0 |

| Bulk Density (g.cm-3) | ≥3.15 | ≥3.15 | ≥3.10 | ≥3.15 | ≥3.10 | ≥3.10 |

| Cold Crushing Strength (MPa) | ≥120 | ≥100 | ≥90 | ≥60 | ≥60 | ≥50 |

| (Nm³.h-¹) Gas Permeability (0.1—1.0 Mpa) | 20-50 | 20-50 | 20-50 | —— | —— | —— |

Long-life Design

Let our technical experts help you find the perfect Purging Plug & Well Block

solution. Contact us today for a customized quote!

Customized Purging Plug & Well Block

Structural Customization: Custom porosity and pore sizes based on ladle capacity, stirring intensity, and gas flow rate.

Size Customization: Custom shapes and dimensions of purging plugs and well blocks.

Customized Formulation: Tailored formulations based on steel grades, smelting processes, and operating conditions, extending refractory service life.